durometer hardness test for rubber|rubber shore hardness chart : agencies Shore (Durometer) Hardness is a measure of the resistance a material has to indentation. Named after its inventor, Albert Ferdinand Shore, Shore hardness offers different scales for measuring the solidity of different materials.(Shore was born in 1876 and lived until 1936, creating the ‘Shore’ scale in the 1920s.) novinha shortinho socado (3,504 results) Report. Sort by : Relevance. Date. Duration. Video quality. Viewed videos. 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. Next. 360p. NOVINHA .

{plog:ftitle_list}

Resultado da Turns out, on the bottom, there's a button that says "Panda Gamepad Pro vs Octopus", and when pressed, it shows a little graph. Octopus works with Keyboard and Mouse, and requires no activation, but it clones the apps in order to work (so you lose all your data while using Octopus, like a second, .

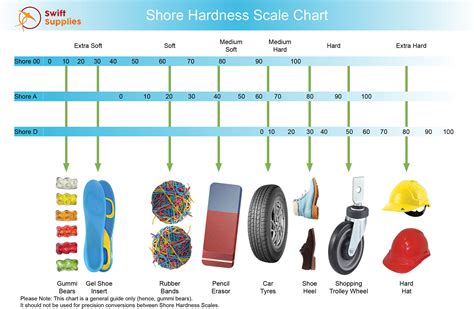

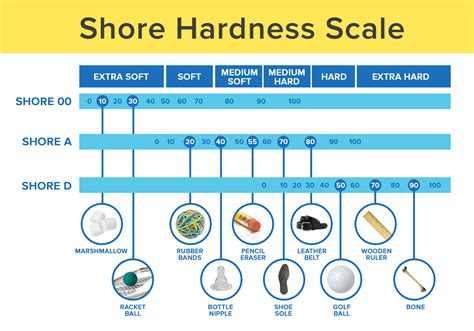

Durable rubber products, depending on their individual consistency, may have a durometer hardness as low as 10 or 20 Shore A all the way up to 100, but the most versatile and practical products will have a rubber hardness rating right in the middle. Rubbers with a durometer hardness between 40 and 70A are seen most commonly.

Test the hardness of thin and irregularly shaped plastic, rubber, and laminate parts, such as O-rings. These testers can be used on products where the surface area is too small for accurate durometer readings with a standard Shore A tester, such as the rounded surface of O-rings. They include O-ring fixtures that hold five standard-sized O-rings in place during testing.

rubber shore hardness chart

rubber hardness scale chart

The hardness of rubber and elastomers according to Shore is determined using test procedures standardized in compliance with ISO 48-4 or ASTM D2240.. In the Shore hardness test, the indentation depth is measured using a spring . The Shore A hardness scale is widely used in the polymer and plastics industry to characterize the hardness of various materials. Manufacturers use durometer testing as a quality check for manufactured products. For example, silicone hardness or rubber hardness can easily be measured and evaluated against manufacturing standards. Shore (Durometer) Hardness is a measure of the resistance a material has to indentation. Named after its inventor, Albert Ferdinand Shore, Shore hardness offers different scales for measuring the solidity of different materials.(Shore was born in 1876 and lived until 1936, creating the ‘Shore’ scale in the 1920s.)Welcome to our ASTM D2240 testing services page for evaluating “Shore hardness” as part of our analysis of plastics and polymers.This standard, ASTM D2240, also known as “Rubber Property—Durometer Hardness,” allows for the measurement of a material’s hardness by indenting the material with a standardized tip under a defined force.

Test the hardness of thin and irregularly shaped plastic, rubber, and laminate parts, such as O-rings. These testers can be used on products where the surface area is too small for accurate durometer readings with a standard Shore A tester, such as the rounded surface of O-rings. They include O-ring fixtures that hold five standard-sized O-rings in place during testing. Standard Test Method for Rubber Property—Durometer Hardness D2240-00 ASTM|D2240-00|en-US Standard Test Method for Rubber Property—Durometer Hardness Standard D2240 Standard Test Method for Rubber Property—Durometer Hardness> new BOS Vol. 09.01 Committee D11 $ 83.00 In stock Scope.CCSi DuroMatters: Durometer Instrument Background. The material is generally termed “rubber or rubber—like”. Specifically, ASTM D2240 durometer hardness testing is restricted to thermoplastic elastomers, vulcanized (thermoset) rubber, elastomeric materials, cellular materials, and some plastics as defined by the ASTM Committee on Terminology in ASTM . The Durometer hardness test is one of the most commonly used measurements to qualitatively assess and compare the mechanical behavior of elastomeric and elastomeric-like materials. This paper presents nonlinear finite element simulations of hardness tests which act to provide a mapping of measured Durometer Shore A and D values to the stress .

A Durometer is a material hardness tester for rubber, elastomer, plastic and other similar compounds. They use a specific spring force and indenter shape combination to measure the indentation depth created and the corresponding resistance, . Dr. Dmitri Kopeliovich Shore hardness is a measure of the resistance of a material to penetration of a spring loaded needle-like indenter. Hardness of Polymers (rubbers, plastics) is usually measured by Shore scales. Shore A scale is used for testing soft Elastomers (rubbers) and other soft polymers. Hardness of hard elastomers and most other polymer . From cure curves to compression set, this complete guide covers all the essential rubber testing methods you need to know. Perfect for anyone in the rubber industry. . Hardness: Durometer: Physical Testing: Cured Rubber: ASTM D2240: Specific Gravity: Specific Gravity Balance: Physical Testing: Cured Rubber: ASTM D792: Dispersion: Dispergrader:

Today, scales Shore 00, Shore A, and Shore D are the most commonly used scales for measuring the hardness of rubber, plastics, silicone, and other polymers. When measuring durometer hardness, follow these steps: Step 1: Choose the appropriate Shore hardness scale to measure the hardness of your test sample. USA Testing Lab for ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness in USA, Indonesia, Philippines, Malaysia, Thailand, Canada, China, India, and all over the World. (302)244-7710 . . ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness. ASTM D2240 encompasses twelve types of rubber hardness . How To Conduct a Hardness Test. . Rubber bands have a hardness of about 20A while a tire tread has a hardness of about 70A. . Hardness (durometer) is measured for TPEs because TPEs are often used in highly abrasive environments in which both abrasion resistance and flexibility are desired. TPE hardness ranges from 20 Shore OO to 90A.

This test method covers twelve types of rubber hardness measurement devices known as durometers: Types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R. The Shore D hardness scale is a test method that determines the hardness of a material. Learn more about it here. . The Shore D Hardness Scale is a method and reference system for measuring the hardness of materials such as rubber and plastic with a tool called a durometer. The exact measurement points to how much force a material can handle .D1415 Test Method for Rubber Property—International Hardness D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries F1957 Test Method for Composite Foam Hardness-Durometer Hardness 2.2 ISO Standard:3 ISO/IEC 17025: 1999 General Requirements for the Com-petence of Testing and .Test the hardness of thin and irregularly shaped plastic, rubber, and laminate parts, such as O-rings. These testers can be used on products where the surface area is too small for accurate durometer readings with a standard Shore A tester, such as the rounded surface of O-rings. They include O-ring fixtures that hold five standard-sized O-rings in place during testing.

rubber durometer scale chart

The Shore D Hardness test is also called Durometer Hardness Test. The letter "D" symbolizes the type of durometer used to measure the hardness of a material. It is a dimensionless quantity. It goes between 0 and 100. The higher number of hardness represents the harder material.RUBBER HARDNESS. Elastomeric materials are usually measured with either a Shore A Scale Durometer or an IRHD dead load system. These tests are designed for use with samples approx 6mm thick, and a surface area sufficient to permit at least 3 .Rubber Property Durometer Hardness 1 This standard is issued under the Þxed designation D2240; the number immediately following the designation indicates the year of . 3.1 This test method permits hardness measurements based on either initial indentation or indentation after a speciÞed period of time, or both. Durometers with maximum reading Rubber Property Durometer Hardness 1 This standard is issued under the Þxed designation D2240; the number immediately following the designation indicates the year of . 3.1 This test method permits hardness measurements based on either initial indentation or indentation after a speciÞed period of time, or both. Durometers with maximum reading

Shore D is reserved for testing hard and semi-rigid plastics and rubbers. Shore Hardness Comparisons. Shore hardness scales offer easily quantified hardness levels. To illustrate, we can compare common objects and materials that exhibit similar hardness. Use the durometer chart below to help you narrow down your shore hardness requirements .Determining the hardness of a material can be done by using a durometer tester. In this video, we demonstrate how to use this device with different types of .

Rubber Property—Durometer Hardness1 This standard is issued under the fixed designation D2240; the number immediately following the designation indicates the year of . 3.1 This test method permits hardness measurements based on either initial indentation or indentation after a specified period of time, or both. Durometers with maximum reading

rubber durometer hardness chart

how hard is 60 durometer

durometer hardness scale for rubber

60a vs 40a durometer

Resultado da 10 de jul. de 2018 · Jogar no Placard é mais simples do é bem mais simples do que parece. Aqui, ensinamos-lhe tudo o que precisa saber para jogar no Placard: Consulte a lista dos eventos disponíveis e anote o número do evento em que está interessado. Seleccione a modalidade da aposta: .

durometer hardness test for rubber|rubber shore hardness chart